EXTRA DUTY

LOCK WASHER

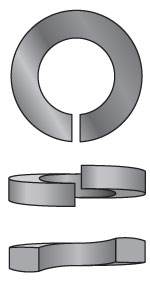

Extra duty lock washers are not totally flat or smooth. They are positioned underneath the nut on a bolt or screw and are designed to prevent the loosening of the nut. These washers are thicker than standard and heavy lock washers and also have a larger outside diameter (O.D.). With a greater thickness, O.D., and bearing area, an extra duty helical spring lock washer can maintain tension under heavy loads and handle extremely high torques.

Extra Duty Helical Spring Lock Washer Function

Bolts are vulnerable to vibrational loosening. An extra duty helical spring lock washer, standard lock washer, and others are designed to prevent a bolt from moving in a rotational direction. Lock washers provide a certain level of resistance to bolt rotation caused by these vibrational forces.

Helical spring lock washers are the most commonly used washers to prevent the loosening of components of a joint. As these washers are subjected to compression, they twist and flatten. They impose a higher level of bolt tension per unit of torque applied. And they also provide strong resistance against loosening caused by vibration and corrosion.

Our Extra Duty Helical Washer

Due to its increased thickness, O.D., and bearing area, an extra duty helical spring lock washer is ideal for heavy duty applications that include very high tightening torques. This washer helps ensure sufficient tension or tightness in applications that involve bolts, screws, and nuts subjected to high loading conditions.

Our extra duty helical washer selection includes a range of size options to accommodate the needs of various applications.

Contact us today for more information about our selection of extra heavy duty lock washers.