HI-LO® FASTENERS

HI-Lo® fasteners are the minimal performance solution for fastening in low pressure environments such as plastic, particle board, masonite, and wood. Hi-Lo thread forming screws include a double-lead thread in which the HI thread possesses greater sharpness than a conventional thread. More material is trapped in between the threads which helps to resist pull-out. This also allows for a lower driving torque.

Advantages:

The various advantages of Hi-Lo screws for plastics and metals include:

- Perfect screw for low-stress applications

- Reduced cracking in plastic bosses

- Smaller sized bosses can be designed to save in material and space

- Increased pull-out resistance

Available Features:

The key features of Hi-Lo screws for metals and plastics include:

- SEMS – add a washer under the head to span larger holes, protect fragile surfaces, and distribute load.

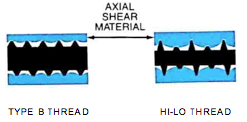

- The high thread 30° included angle displaces less material when it is driven into plastic or wood and, therefore, requires lower driving torques. A greater amount of material remains between the high threads, increasing the stripping torque. Low driving torque and high stripping torque provide maximum protection against stripping problems.

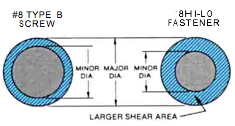

The thread configuration of Hi-Lo screws includes a smaller minor diameter than a standard screw. The high threads of these Hi-Lo -fasteners produce a deeper cut into the material resulting in more material volume between the threads. More volume of material also engages with the sharp, high thread. The area of axial shear is also increased. All of this leads to a screw with strong fastening capability and greater pullout resistance.